In everyday life, nearly everyone has experienced the annoyance of glare, especially when interacting with displays or glass screens. Glare comes not only from direct light sources but also from reflections on the glass surface. When operating equipment, the reflected light from objects outside the display can obscure the content on the screen. This becomes even more critical in high-precision fields like medical displays and industrial control panels, where glare can lead to errors, misjudgments, and potentially serious consequences. Thus, effectively minimizing glass reflection has become a key issue for many industries.

The solution to this problem is the advent of AG (Anti-Glare) glass technology.

What is AG Anti-Glare Glass Technology?

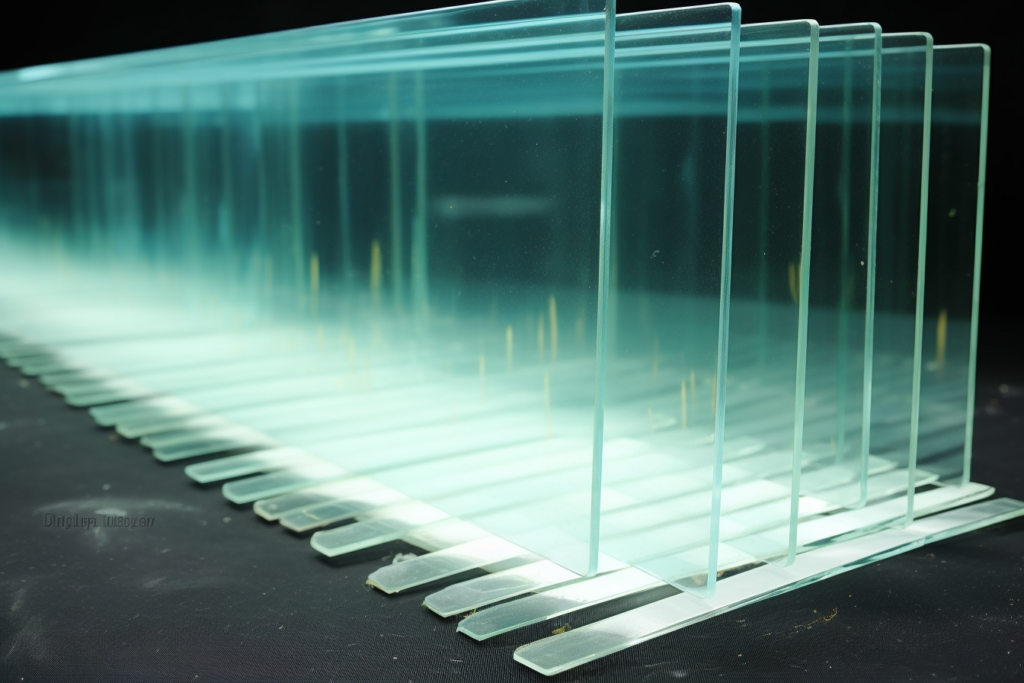

Simply put, AG glass technology involves reducing the reflection from the glass surface to minimize light interference and improve visibility. Ordinary glass tends to have a high reflection rate, but with AG treatment, the surface reflection is significantly reduced, resulting in clearer display content and a more comfortable viewing experience.

AG Glass Anti-Glare Technologies

Currently, there are two main types of AG glass technologies: etching-based anti-glare and coating-based anti-glare.

- Etched Anti-Glare Glass: Etched AG glass uses a chemical etching process to create a uniform microstructure on the surface, significantly reducing reflections. This process is more complex and expensive, making it suitable for high-end applications such as medical equipment and industrial control displays.

- Coating Anti-Glare Glass: Coating-based AG glass involves spraying one or more layers of anti-glare liquid (AG solution) onto the glass surface to enhance light diffusion, reducing the reflection intensity. This method is more cost-effective and simple, which is why most AG glass products available in the market today use this technology.

Comparison of Etched and Coated Anti-Glare Glass

When comparing etched AG glass with coated AG glass, several distinct advantages emerge for the former:

- Higher Surface Hardness and Strength

- Etched AG Glass has a surface hardness of 7H (pencil hardness), providing excellent scratch resistance, which is crucial for environments that involve frequent handling, such as industrial controls and medical displays.

- Coated AG Glass, on the other hand, has a lower surface hardness, typically ranging from 3H to 4H, and is more prone to scratches and wear.

- Longer Lifespan

- Etched Glass retains its strength and durability over time, similar to strengthened glass, and is not easily affected by environmental factors such as cleaning chemicals or UV exposure. Under normal usage, etched glass can last for over 10 years.

- Coated Glass's surface treatment may degrade over time, as the coating is more susceptible to wear, aging, and peeling, shortening its overall lifespan.

- Superior Fingerprint Resistance and Dust Repellence

- Etched Glass does not have a coating, so it naturally resists fingerprints and dust buildup. It remains clean and easy to maintain. In fact, etched glass typically resists fingerprints up to 99% and does not lose this ability over time.

- Coated Glass, due to its surface coating, is more prone to fingerprint marks and oil stains. Cleaning can also damage the coating, diminishing its anti-glare effect.

- Optical Performance

- Etched Anti-Glare Glass offers superior optical properties, significantly reducing glare spots and providing more even brightness, which ensures clearer visibility. The reflectivity is typically below 1% and maintains excellent optical uniformity.

- Coated Anti-Glare Glass tends to have lower optical performance, with the overall reflectivity typically ranging between 2%-3%, and the optical uniformity is not as high.

- Improved Brightness and Clarity

- Etched Glass reduces light interference, improves contrast, and enhances visibility. Depending on the gloss level, the haze of etched glass typically ranges from 2% to 12%, making it ideal for applications that require high contrast and clear visibility.

- Coated Glass has a higher haze level, usually between 10% to 20%, which can impact the screen’s brightness and clarity.

- Ease of Further Glass Processing

- Etched Glass can be easily processed further, such as cutting, drilling, or bending, without compromising its strength. The strength of etched glass is typically DOL > 8μm and CS > 450MPa, providing excellent stability and impact resistance during subsequent processing.

- Coated Glass, since it undergoes processing first and then coating, may suffer from a weakened overall strength due to the coating process, which could compromise its impact resistance and durability.

SZ Claritech’s AG Glass: Advantages and Technical Specifications

As a leading AG glass supplier, SZ Claritech is committed to providing high-quality anti-glare glass solutions. Below are the key technical specifications of SZ Claritech's AG glass:

- Reflectivity: Typically less than 1%, reducing reflection by over 90% compared to standard glass.

- Surface Hardness: Etched glass reaches a 7H pencil hardness, offering excellent scratch resistance.

- Light Transmission: For glass thicknesses below 4mm, the light transmission can reach >88%, ensuring clear and bright displays. For thicker glass, the light transmission usually falls below 88%.

- Haze: Depending on gloss level, etched glass typically has a haze ranging from 2% to 12%, ideal for high-precision display applications.

- Fingerprint Resistance: The anti-fingerprint capability is 99% or more, keeping the surface clean.

- Lifespan: Under normal usage, SZ Claritech’s etched AG glass can last 10+ years.

Why Are More Clients Choosing SZ Claritech’s AG Glass?

As industrial technology continues to evolve, the demands for high-performance display glass are also increasing. SZ Claritech has earned the trust of an expanding client base due to its innovative AG anti-glare technology and superior product quality.

First, SZ Claritech’s AG glass boasts excellent scratch resistance, fingerprint resistance, and dust repellence, making it ideal for high-precision, high-frequency usage in fields like industrial control and medical displays. Furthermore, SZ Claritech’s rigorous manufacturing processes ensure that their AG glass provides long-term optical performance and durability.

This combination of superior performance, durability, and cost-effectiveness is why more and more clients are choosing SZ Claritech AG glass, relying on it to provide clear, sharp, and comfortable visual experiences in a variety of environments.

Conclusion

AG anti-glare glass, with its excellent optical properties, durability, and light reflection reduction, is widely used in high-precision fields such as medical equipment and industrial control. SZ Claritech, with its advanced AG anti-glare technology and meticulous production process, has become a trusted name among customers. As display technology continues to advance, the demand for AG glass will only grow, and SZ Claritech will continue to provide top-quality anti-glare solutions for its clients.