What is the Dead Front Effect?

The dead front effect means that when the screen is on, the display content is clearly visible; when the screen is off, the screen turns black and blends seamlessly with the border. This design not only enhances the modern and high-end look of the product but also reduces external distractions and improves the viewing experience.

Why Choose Dead Front Cover Glass?

As consumer demands for product appearance and user experience continue to rise, designers focus more on differentiation and innovation. Dead front cover glass is popular in the market for its unique aesthetics and premium user experience.

Applications of Dead Front Cover Glass

Dead front cover glass is widely used in smart wearable devices, smartphones, smart homes, smart control centers, engineering vehicles, train displays, medical devices, and vehicle displays.

Five Common Methods to Achieve the Dead Front Effect

Semi-Transparent Ink Printing (Small Sizes 1-2 Inches)

For small cover glass (1-2 inches), semi-transparent ink printing is commonly used. After CNC grinding and strengthening, semi-transparent IR ink is printed on the window area of the glass. This creates a dead front effect when the screen is off.

Considerations

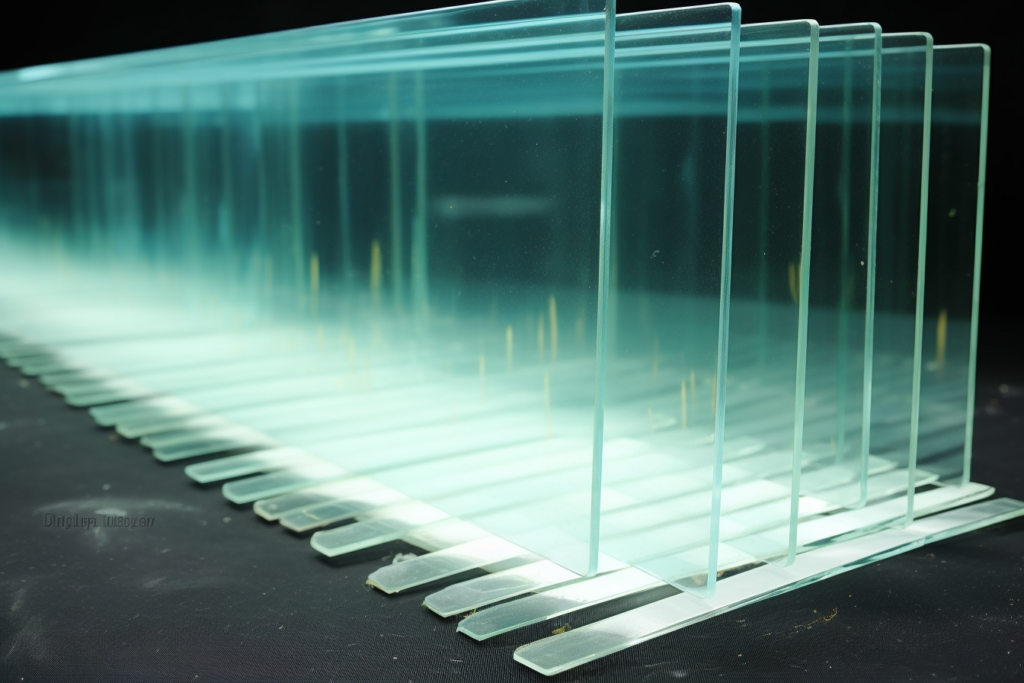

Gray Glass (Medium to Large Sizes 7-32 Inches)

The dead front effect can also be achieved using semi-transparent materials like gray glass. This glass is made by adding inorganic metal oxide colorants to turn clear glass into dark gray, low-transmittance glass. For medium to large cover glass (7-32 inches), gray glass with a thickness of less than 4mm is typically used. Gray glass has low transmittance and stable quality, avoiding defects like orange peel and blade marks that can occur with printing. This is the most recommended method for achieving a dead front effect. Adjusting ink colors can lead to color differences, and module colors can vary between batches.

Black OCA/OCR

Adjusting the color of optical adhesive can reduce the color difference between the display area and the border, achieving a uniform black effect.

Adjusting Cover Glass Border Color (For Thickness Limitations)

When gray glass thickness is not suitable, the cover glass border color can be adjusted to match the module color, achieving a dead front effect. This method is cost-effective and suitable for applications with thickness limitations.

Glass Plating (Low Yield, High Cost)

Unlike semi-transparent ink printing, glass plating involves coating the glass with an inorganic film. This film adjusts the reflection, transmission, and color difference in the window area to achieve a dead front effect. Coatings can have up to 80% transmittance and less than 2% reflectance. However, glass plating has low yield and uncontrollable costs, making it unsuitable for large-scale use.

Main Factors Affecting the Dead Front Effect

The dead front effect is influenced by multiple factors, including TFT display, polarizer, lamination method, adhesive, border ink, and coating. Therefore, choosing an experienced cover glass supplier is essential to ensure the desired effect.

Do AG/AR/AF Treatments Affect the Dead Front Effect?

Anti-glare (AG), anti-reflective (AR), and anti-fingerprint (AF) treatments can enhance product aesthetics and user experience but may affect the dead front effect. High-quality anti-glare etched glass does not impact transmittance, so choosing a reliable supplier is crucial.

Conclusion

SZ ClariTech Co., Ltd. has nearly 10 years of experience in the cover glass processing industry and is eager to share our extensive experience and case studies across various industries. If you are interested in the dead front effect, we can discuss and exchange ideas to help you find more design inspirations!

I hope this version meets your needs better. Let me know if you need further modifications or additions.