Custom AG Cover Glass

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

AG Glass, or Anti-Glare Glass, is a specialized type of glass renowned for its anti-reflective properties. It undergoes a unique treatment process that makes it ideal for industrial, medical, and military applications. This glass significantly reduces light reflection, thereby improving the readability of display screens. At TouchTechglass, we exclusively utilize etched AG glass to ensure top-notch anti-reflective performance.

Here are some of the most common customization options you may encounter:

Applications of AG Glass in Various Fields

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

Maritime

Navigation Instrument Screens: Improves readability in bright light conditions.

Control Panels: Reduces glare in ship control rooms, enhancing operational safety.

Military

Military Equipment Displays: Maintains clear visibility outdoors or under bright conditions.

Consoles and Monitors: Ensures optimal visual quality in various environmental settings.

Geology

Field Equipment: Enhances screen readability under direct sunlight.

Laboratory Analytical Instruments: Reduces indoor lighting interference, increasing data accuracy.

Navigation

Vehicle Navigation Systems: Minimizes visual disturbances caused by sunlight reflection.

Handheld GPS Devices: Provides clearer display in outdoor settings.

Smart Home

Home Control Panels: Maintains clear display under various indoor lighting conditions.

Smart Appliance Screens: Enhances visual experience while using smart home appliances.

Payment Systems

Self-service Terminals: Keeps display clear and readable in outdoor or bright commercial environments.

Mobile Payment Devices: Improves user experience under outdoor or bright light conditions.

Product Gallery

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

The Advantage of AG Cover Glass

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

Our Touch Tech Glass team excels in delivering top-notch custom glass solutions, covering everything from drawing to cover glass.

We offer a full range of services, from pre-sales consultation to after-sales support, ensuring excellence at every step. Discover why we are the preferred choice in glass technology through the details.

Anti-Glare Performance

In environments with challenging lighting conditions, our AG Glass ensures that your screen's content remains vivid and easily visible.

Anti-Fingerprint and Easy to Clean

Our glass is coated with an AF layer, making it resistant to fingerprints and dirt, while also being easy to clean

Low Haze, High Clarity

With low haze and uniform particle distribution, our AG Cover Glass offers superior clarity and a delightful touch experience.

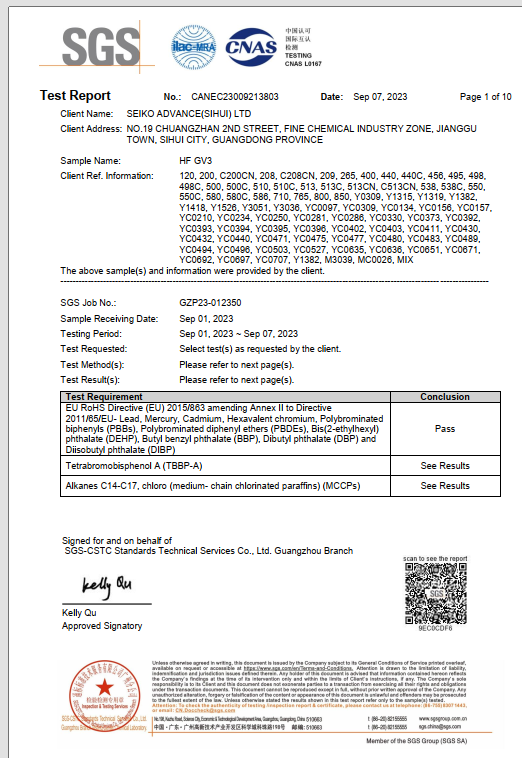

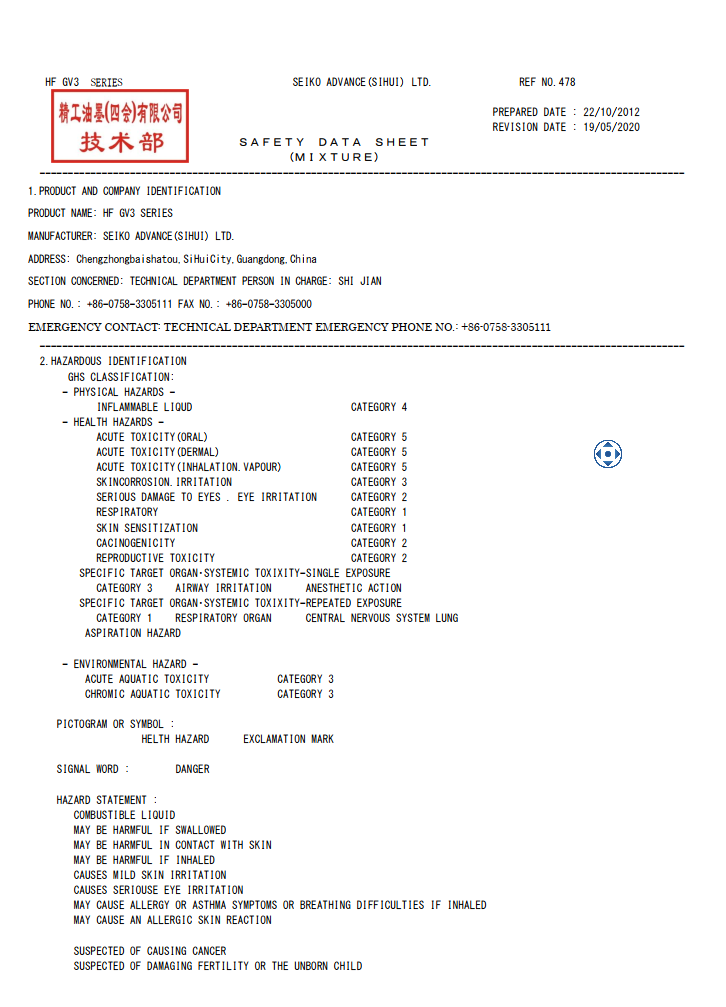

Compliance with Regulations

Rest assured, our product adheres to RoHS and REACH regulations, reflecting our commitment to quality and safety.

Custom AG Glass Cover Plate Production Process

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

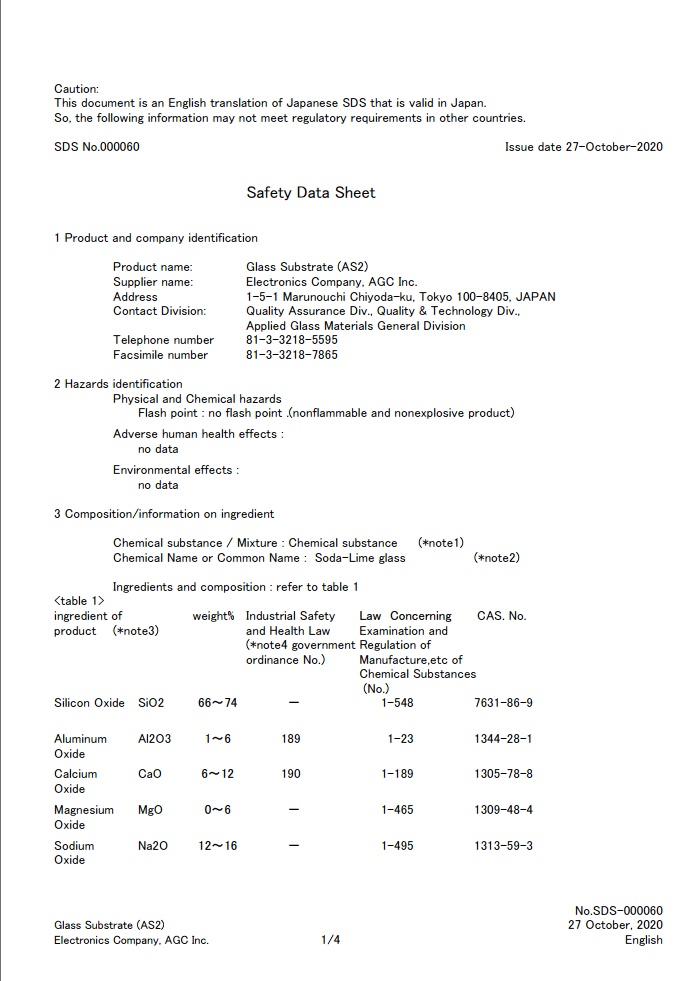

Row Material

Our AG glass, crafted from premium etching materials, ensures a durable anti-glare effect. We maintain a ready stock, ensuring immediate availability for your needs.

Chemical Strengthen

Our AG glass undergoes sodium-potassium ion exchange, achieving a 6H hardness, over 650 MPa compressive stress, and a depth of layer beyond 40 micrometers, significantly boosting its impact resistance.

Ultrasonic Cleaning

Our ultrasonic automatic cleaning machine ensures thorough cleaning before and after each process, guaranteeing impeccable cleanliness and high purity levels in the final product.

CNC workshop

Our Glass Cover Plate CNC Workshop excels in precision dimension processing, including intricate tasks like step glass fabrication and custom shaping, ensuring high accuracy and quality in every piece

Physically Strengthen

Durability: Increases strength and wear resistance.

Impact Resistance: Withstands greater impacts.

Temperature Tolerance: Suitable for various environments.

Safety: Breaks into small, safer pieces.

Aesthetics: Enhanced appearance for high-end use.

Silk Screen Printing

Custom Designs: Complex, precise, client-specific.

Durability: Resistant to wear and chemicals.

Versatility: Wide color and effect range.

Cost-Efficiency: Economical for bulk production.

Adaptability: Suitable for extreme conditions.

Quality and Certification: Ensuring Compliance with Global Standards

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

Custom Glass Cover Plate Packaging Process

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

Electrostatic Protective Film Packaging

Each glass cover plate is wrapped in double-sided electrostatic protective film.

For AG glass, we use a special protective film to ensure its safety and integrity during transportation.

Vacuum Sealing and Product Labeling

Every glass cover plate packaged in a PE bag is vacuum-sealed, with the PE bag having a thickness of 0.14mm. Each small package is clearly labeled with product details, such as “5 inches, 100 pcs/bag”.

Carton or Wooden Box Packaging

The glass cover plates are packed in either cartons or wooden boxes, which require no fumigation. Each box is cushioned on all six sides with foam, ensuring safety during transit. Shipment reports, drawings, product lists, and material ICP data are included with the goods.

Global Shipping and Flexible Transportation Solutions

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

Global Shipping Partnerships

Collaborating with FedEx, DHL, UPS, TNT,EMS and others to ensure safe, fast global delivery.

Real-Time Tracking Follow ups

Detailed shipment tracking from dispatch to delivery, keeping you informed.

Flexible Shipping Options

Sea, air, and express options tailored to your time and cost needs, with expert guidance.

FAQ

In this page header section, you can provide details about the purpose of the page. This helps users quickly understand what to expect from the page content.

We believe in providing transparent pricing and there are no hidden fees or charges beyond the initial quote for our plumbing services. Our quotes are carefully calculated based on the scope of work and the time and materials needed to complete the job.

We give detailed, itemized quotes that break down how much each part of the job will cost. We believe that our customers have the right to know exactly what they're paying for, which is why we provide clear and detailed pricing information.

Size Range: We offer a wide range of sizes from 1 to 32 inches, catering to various requirements.

Thickness Variations: Our products are available in multiple thicknesses, including 0.5, 0.7, 1.0, 2.0, 3.0, and 4.0 mm, to suit different applications.

Anti-Glare Effectiveness: We provide anti-glare solutions with a gloss level ranging from 30 to 110, ensuring optimal visibility and user comfort. Single and Double-Sided Options: Both single and double-sided anti-glare treatments are available, offering flexibility in usage.

We are pleased to offer samples with different levels of anti-glare treatment for customer evaluation, ensuring you can select the most suitable product for your needs.

Our monthly production capacity stands at 350,000 pcs, enabling us to handle large orders efficiently.

The standard delivery time for orders is 5-15 business days upon receipt of payment, ensuring prompt and reliable fulfillment.

Please contact us via email at info@touchtechglass.com, Skype, WeChat, WhatsApp, or direct call. Include the product drawings, dimensions, delivery address, and required quantity in your inquiry. If there are any other special customization needs, please mention them as well.

Robust Quality Management System: We adhere to ISO 9001 standards and have a comprehensive quality management system in place, ensuring all processes meet international norms.

QC Engineering Drawings: Strict QC engineering drawings are followed to ensure production is carried out precisely according to customer specifications.

In-Process Quality Control: Our IPQC (In-Process Quality Control) team verifies product performance at every production stage to maintain quality.

100% Visual Inspection: We conduct a 100% visual inspection of all products to ensure each item meets our high aesthetic standards.)

Yes, we can. All our quality inspection reports during the production process are recorded and maintained in Chinese. If required, we can translate these reports into English for our clients. Additionally, with each shipment, we provide an English version of the shipping inspection report.

We accept various payment methods, including T/T, Western Union, L/C, PayPal, and Cash, offering flexibility to our clients.