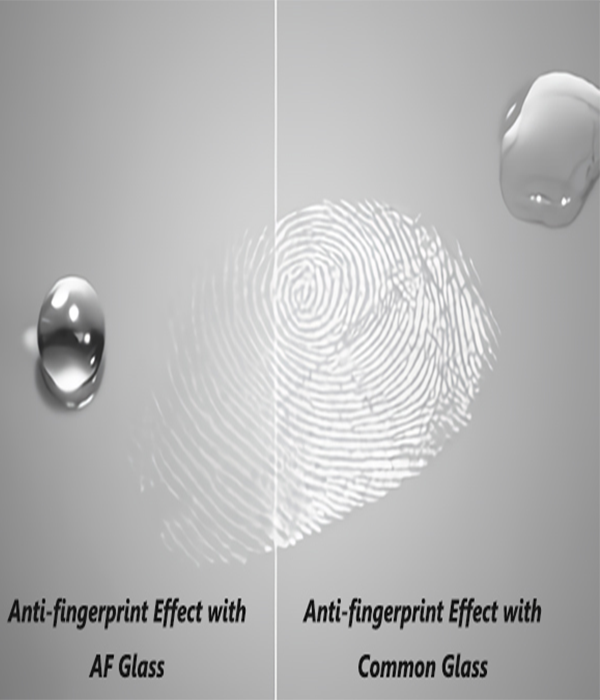

AF glass (Anti-Fingerprint Glass) is a type of glass with a special coating on its surface that effectively prevents fingerprints and smudges from adhering while being easy to clean. This coating typically consists of a combination of hydrophobic and oleophobic materials, forming a protective layer that reduces the adherence of fingerprints and dirt.

The manufacturing process of AF glass mainly includes the following steps:

Cleaning

The finished glass cover needs to undergo thorough cleaning before coating to remove dust, grease, and other impurities. This step usually employs ultrasonic cleaning methods.

Coating

Through spraying or dipping technology, a uniform anti-fingerprint coating is applied to the glass surface. The coating materials are typically hydrophobic and oleophobic chemicals that reduce the adherence of fingerprints and smudges.

Curing

After coating, the layers need to be cured to enhance adhesion and durability. Curing is usually done in a high-temperature furnace, with the temperature and time adjusted according to the coating materials and thickness.

Inspection

After curing, the AF glass undergoes comprehensive quality inspection, including coating uniformity, anti-fingerprint effectiveness, abrasion resistance, and other indicators, to ensure each piece meets design requirements.

Packaging

The finished AF glass is cleaned and dried, then packaged in a dust-proof manner to ensure it remains uncontaminated and undamaged during transportation and storage.

AF GLASS Acceptance Standards

Our AF glass must pass strict acceptance standards before leaving the factory, including:

Coating Quality

Light Transmission

Surface Hardness

Ease of Cleaning

Size and Thickness

Production Capacity and Lead Time

Supplier Reputation and Service

When purchasing AF glass, it is important to consider coating quality, light transmission, surface hardness, ease of cleaning, size and thickness, production capacity and lead time, and supplier reputation and service. By thoroughly understanding these key points, you can ensure that the AF glass you purchase will meet specific application requirements and provide excellent performance and user experience.