As demand grows for cover glass that combines aesthetic appeal with technical precision, we’ve developed a 2mm elliptical cover glass made from clear float glass, complete with functional cutouts, printed markers, and precise tolerances across all dimensions. Our manufacturing process upholds rigorous standards to meet the expectations of buyers and engineering teams alike.

Design and Functional Requirements

Ergonomic Elliptical Shape

This cover glass features a sleek, ergonomic elliptical design. Using precision CNC cutting, we’ve achieved consistently smooth edges with a tolerance of ±0.05mm, avoiding any stress points. This attention to precision not only enhances durability but also significantly reduces the risk of cracking, providing a seamless, high-end look.

Precision Circular Cutout at the Bottom

A 5mm circular cutout at the bottom is CNC-machined to integrate smoothly with control knobs or switches. We maintain an edge tolerance of ±0.02mm here, ensuring a perfect fit. This level of accuracy minimizes assembly time and ensures consistent quality, reducing the need for rework or adjustments.

Durable and Precisely Aligned Volume Markers

On both sides of the cover glass, volume markers are positioned to align exactly with physical knobs. Using low-temperature ink printing, these markers are designed to withstand frequent use without fading. We keep a positioning tolerance of ±0.1mm to guarantee each marker sits accurately in relation to the knob, ensuring an intuitive and visually accurate user experience.

Seamless Power Button Slot

At the top, a 3mm-wide slot is precisely milled for the power button. This slot’s function and appearance are both critical, with tolerances held to ±0.03mm. The result is a perfectly integrated slot that combines structural strength with a satisfying tactile experience.

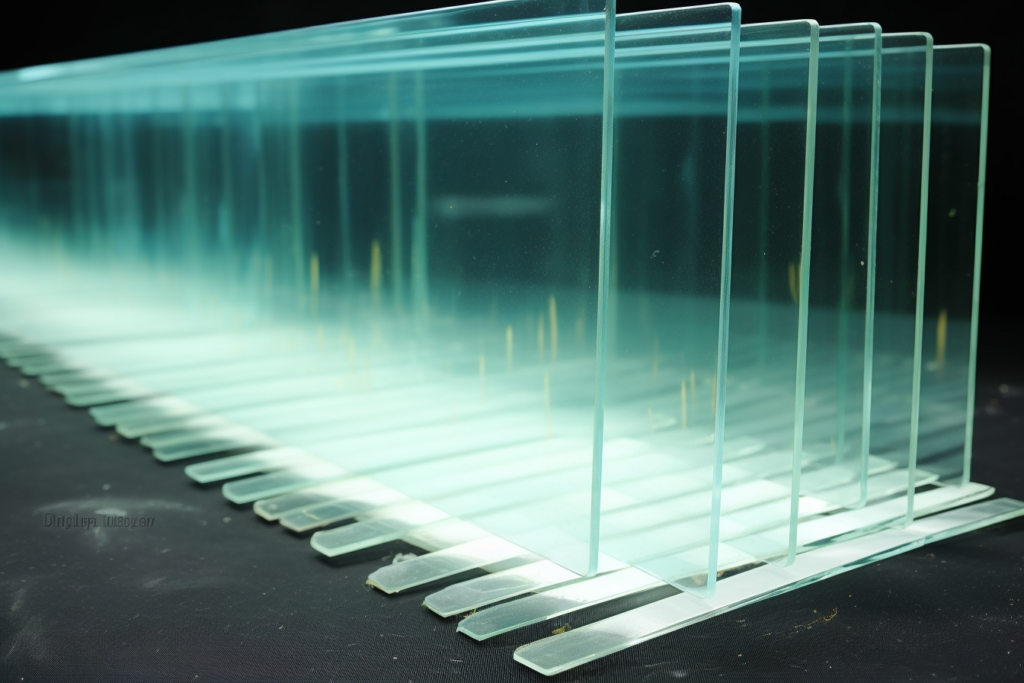

Material Choice: 2mm Clear Float Glass

We selected 2mm clear float glass for its excellent optical clarity and scratch resistance. With light transmittance over 92%, this cover glass keeps display visuals sharp and vibrant. Additionally, it’s treated to enhance hardness, reaching a Mohs rating of 7, which helps protect against daily wear and tear.

Key Manufacturing Challenges and Solutions

High-Precision Cutting for Consistency

The elliptical shape requires careful CNC control to achieve a uniform cut with no stress points. Our CNC machines maintain tolerances within ±0.05mm, ensuring smooth curves and consistent quality. CAD/CAM software directs each cut, guaranteeing that each piece meets the rigorous standards essential for large production runs, which reduces variance and supports procurement and engineering quality expectations.

Edge Polishing for Durability

The edges around the cutouts are finely polished to eliminate micro-cracks or imperfections. This polishing process increases the cover glass’s strength, ensuring it withstands regular use without compromising integrity—an essential feature for engineering teams focused on durability.

Low-Temperature Ink Printing for Volume Markers

The volume markers are printed using low-temperature ink, cured in multiple stages at 90°C. This technique enhances adhesion and color retention, preventing fading even after 10,000 use cycles. This durability aligns with the reliability standards expected by buyers and ensures functional clarity for engineering applications.

Protective Coatings

For added durability, we apply scratch-resistant and anti-fingerprint (AF) coatings. Rated at 5H hardness, these coatings protect against scratches and keep the cover glass free from smudges. Buyers benefit from a pristine finish, while engineers appreciate the added protection during handling and assembly.

Quality Control and Testing

Every cover glass undergoes extensive testing to ensure it meets strict specifications:

- Dimensional and Tolerance Testing: Precision instruments verify all dimensions to minimize assembly issues and ensure product consistency.

- Cutout Positioning Checks: Laser-guided tools confirm exact cutout placement, making each cover glass fully compatible with control components.

- Surface Durability Testing: Microscopic inspection detects surface flaws, while durability tests confirm that coatings withstand daily use and maintain high-quality appearance over time.

Conclusion

Our elliptical cover glass combines visual appeal with precise functionality. With exact CNC machining, durable printed markers, and protective coatings, this product meets the standards of both buyers and engineers. Buyers appreciate its refined appearance and resilience, while engineers value its precision, durability, and seamless performance—making this cover glass an ideal choice for high-end devices.