Introduction

In the modern age of electronic devices, the demand for high-quality glass covers has surged. Different types of glass, such as AG (Anti-Glare), AR (Anti-Reflective), and AF (Anti-Fingerprint) glasses, serve specific purposes in various applications. This guide will delve into the differences, applications, and how to choose the right cover glass for your needs.

Ways to Reduce Glass Reflection

Ordinary glass can reflect light, causing glare and visibility issues. There are several ways to reduce this reflection:

AR Coating: Optical coatings are applied to the glass to reduce reflectivity and increase transmittance.

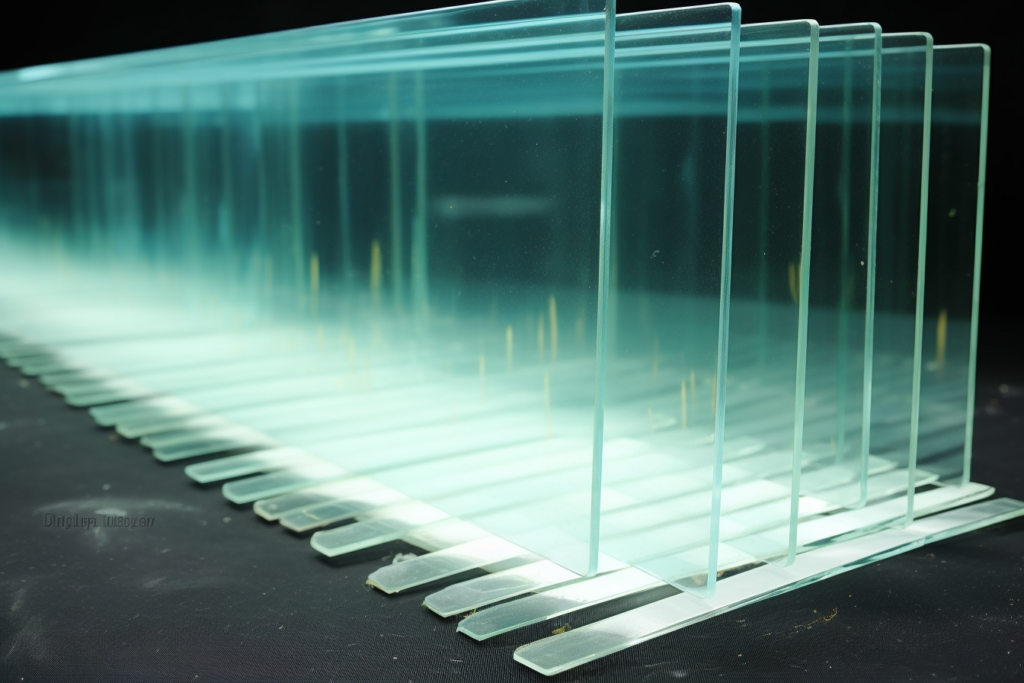

AG Coating: The glass surface is chemically etched to create a matte finish, diffusing light and reducing glare.

Differences between AG Glass, AR Glass, AF Glass, and AG+AR+AF Glass

| Aspect | AG Glass (Anti-Glare) | AR Glass (Anti-Reflective) | AF Glass (Anti-Fingerprint) | AG+AR+AF Glass (Anti-Glare + Anti-Reflective + Anti-Fingerprint) |

|---|---|---|---|---|

| Definition | Chemically etched to create a matte surface that diffuses light | Optical coating on one or both sides to reduce reflectivity | Oleophobic coating to resist fingerprints and smudges | Combination of anti-glare, anti-reflective, and anti-fingerprint coatings |

| Key Benefits | - Reduces glare<br>- Creates a non-reflective surface | - Increases transmittance (>99%)<br>- Reduces reflectivity (<1%) | - Resists fingerprints<br>- Easier to clean | - Reduces glare and reflectivity<br>- Resistant to fingerprints and smudges |

| Transmittance | 88%-91% (up to ~93% for high-quality glass) | > 93% (up to 99%) | Typically high transmittance | Typically > 90% due to combined coatings |

| Tempering Process | Surface treated before tempering | Coated after tempering | Coated after tempering | Combined coating processes; typically applied after tempering |

| Size Considerations | Cost-effective for larger sizes | Limited by processing size; best for small-sized applications like camera lenses | Generally not size-limited | Size may be limited by combined processing technology |

| Durability | More durable and resistant due to etched surface | Coating may wear off over time in harsh environments | Coating may wear off over time in harsh environments | High durability due to combined surface treatments |

| Maintenance | Easier to clean and maintain due to robust surface treatment | Requires careful cleaning to avoid damaging the coating | Very easy to clean and maintain | Very easy to clean; resistant to fingerprints and smudges |

| Customization | Customizable in surface roughness and texture | Customizable in type and number of coatings | Typically less customizable | Highly customizable to balance glare, reflection, and fingerprint resistance |

| Operating Environment | Best for environments with strong/direct light (e.g., outdoors) | Best for controlled environments needing high clarity and minimal reflection | Ideal for high-touch environments | Versatile for both indoor and outdoor use; ideal for touchscreens and high-usage environments |

Applications of AG Glass, AR Glass, AF Glass, and AG+AR+AF Glass

| Applications | AG Glass | AR Glass | AF Glass | AG+AR+AF Glass |

|---|---|---|---|---|

| Clear Visual Environment & Visibility in Strong Light | ATMs, cash registers, public transportation displays, fuel dispensers | Not applicable | Public touchscreens | Touchscreens and high-usage public displays |

| Security Cameras | Not applicable | Camera lenses | Screens | Screens and camera lenses |

| Laptops | Touchpads | Display screens | Touchscreens | Touchscreens and display screens |

| Monitoring Devices | Not applicable | Indoor and outdoor surveillance | Not applicable | High-usage screens |

| Smart Identification Devices | Not applicable | Fingerprint, face, and pupil recognition systems | Touchscreens | Touchscreens and identification systems |

| Safe and Reliable Operation | Aerospace and navigation equipment, military equipment, industrial equipment (e.g., excavators, forestry machines) | Not applicable | High-touch industrial equipment | Touchscreens and high-usage equipment in harsh environments |

How to Choose the Right Cover Glass

| Criteria | Recommendation |

|---|---|

| Transmittance | - Moderate transmittance: AG Glass<br>- High transmittance (>93%): AR Glass<br>- High transmittance and smudge resistance: AF Glass<br>- Combined benefits: AG+AR+AF Glass |

| Tempering Process | - Surface treated before tempering: AG Glass<br>- Coating after tempering: AR Glass, AF Glass<br>- Combined coating processes: AG+AR+AF Glass |

| Size | - Larger sizes: AG Glass<br>- Small-sized applications: AR Glass, AF Glass<br>- Depends on processing technology: AG+AR+AF Glass |

| Operating Environment | - Strong light environments: AG Glass<br>- Controlled environments: AR Glass, AF Glass<br>- Versatile use (indoor and outdoor): AG+AR+AF Glass |

| Durability and Maintenance | - Durable and easy to maintain: AG Glass, AF Glass<br>- Highly durable and easy to clean: AG+AR+AF Glass |

| Customization Needs | - Surface texture customization: AG Glass<br>- Optical coating customization: AR Glass<br>- Smudge resistance customization: AF Glass<br>- Highly customizable for multiple features: AG+AR+AF Glass |

Practical Considerations

| Consideration | AG Glass | AR Glass | AF Glass | AG+AR+AF Glass |

|---|---|---|---|---|

| Durability | More durable and resistant due to etched surface | Coating may wear off over time in harsh environments | Coating may wear off over time in harsh environments | High durability due to combined surface treatments |

| Maintenance | Easier to clean and maintain due to robust surface treatment | Requires careful cleaning to avoid damaging the coating | Very easy to clean and maintain | Very easy to clean; resistant to fingerprints and smudges |

| Customization | Customizable in surface roughness and texture | Customizable in type and number of coatings | Typically less customizable | Highly customizable to balance glare, reflection, and fingerprint resistance |

Conclusion

Customer Queries: Clarify differences and guide customers on choosing the right glass.

Combined Use: AG glass is often used alone; AR glass is typically paired with AF glass, and AG glass can also be paired with AF glass. AG+AR+AF combinations exist but are rare.

Cost Considerations: Emphasize cost increases and the importance of choosing based on specific product needs.

For expert guidance on selecting the right cover glass for your products, and to explore our wide range of high-quality AG, AR, AF, and AG+AR+AF glass options, contact SZ ClariTech today. Our team is ready to provide customized solutions to meet your unique needs. Reach out to us at zoe@touchtechglass.com or visit our website www.touchtechglass.com for more information.